- Article

- Poultry

- Pathogens

Breaking the Cycle: Reducing Salmonella Pressure Before Processing

Key takeaways

- Salmonella remains a persistent industry challenge, often carried by without clinical signs.

- High intestinal colonization increases contamination risks during handling and processing.

- Jefo Protected Organic Acids + Essential Oils act synergistically to weaken Salmonella and reduce its survival in the gut.

- Jefo Protected Organic Acids + Essential Oils consistently reduce Salmonella levels across strains and improve downstream outcomes.

A long-standing industry problem

Salmonella has remained a concern for the poultry industry despite advances in management, monitoring, and processing controls. Its persistence continues to drive regulatory attention, product recalls, and added scrutiny throughout the supply chain. One of the main challenges is that birds can carry Salmonella without showing any clinical signs, making it difficult to identify and control before they enter the processing plant.

What Salmonella is and why it matters

Salmonella is a genus of bacteria capable of colonizing the intestinal tract of poultry. Several strains commonly associated with broiler production, including Salmonella Enteritidis, Salmonella Heidelberg, and Salmonella Typhimurium, are also known to cause illness in humans. When the intestinal colonization levels are high, the likelihood of contamination during the handling and processing increases, even in well-managed systems.

How protected organic acids and essential oils act on Salmonella

Organic acids and essential oils work together to target Salmonella in synergistic ways. Essential oils interact with the bacterial cell membrane, weakening its structure and increasing permeability for the entry of other compounds like organic acids. Organic acids, in turn, disrupt normal metabolic functions and make it harder for Salmonella to survive and multiply. When delivered in a protected form, these compounds can reach key sections of the digestive tract in their active form, where Salmonella typically establishes. Together, this combination creates intestinal conditions that reduce Salmonella viability and limit its ability to persist in the intestine.

Why on-farm Salmonella reduction is critical

Once birds reach the processing plant, opportunities to manage Salmonella become more limited. Lowering Salmonella pressure earlier in production helps reduce the overall load entering the plant and supports downstream control measures. In addition, reducing on-farm Salmonella load is key to lowering environmental contamination, helping to reduce the pressure on future flocks. For this reason, strategies that reduce intestinal colonization prior to slaughter play an important role in broader control programs.

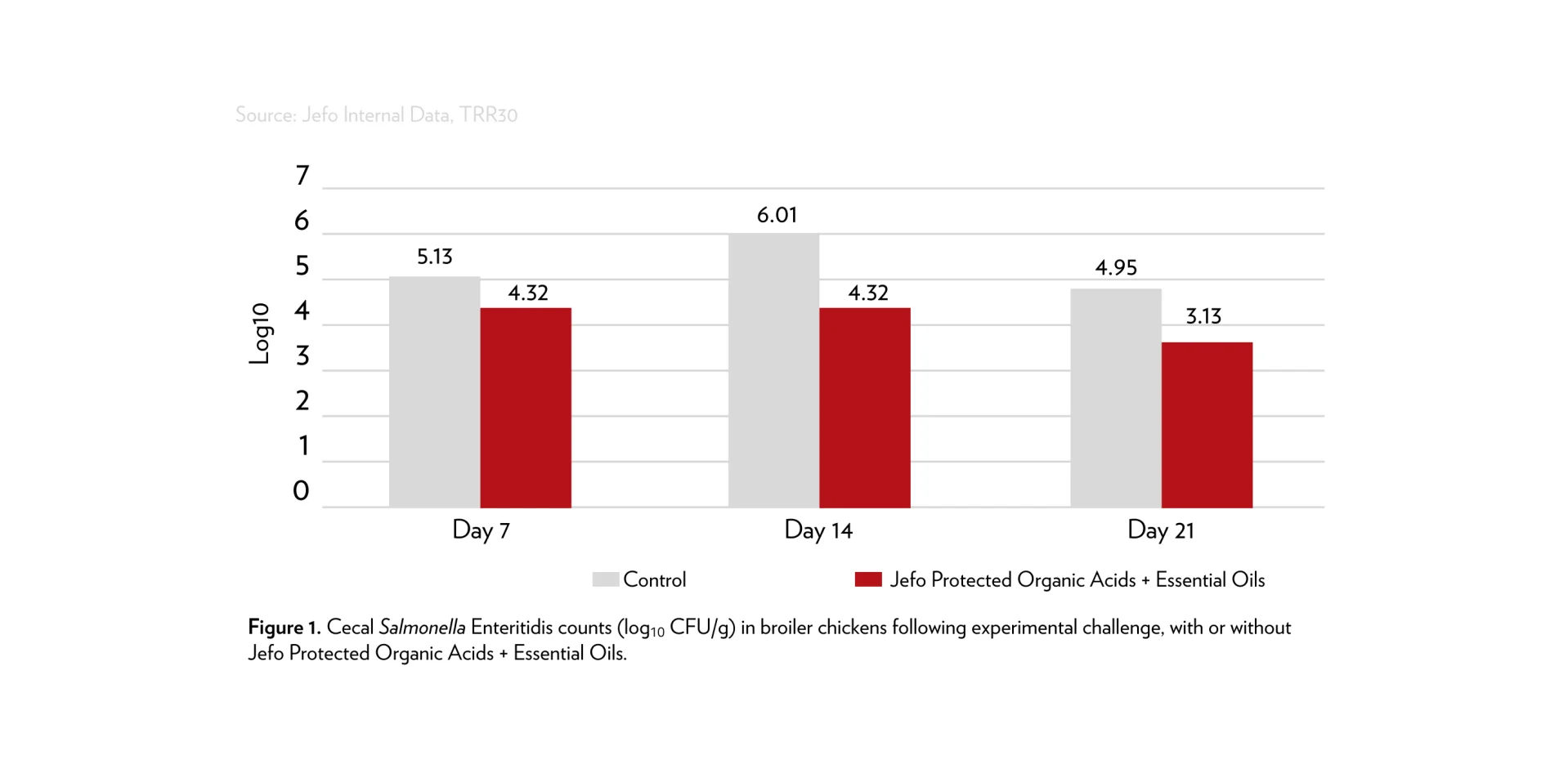

Consistent results across Salmonella strains

Research has demonstrated consistent reductions in Salmonella counts in broilers supplemented with Jefo Protected Organic Acids + Essential Oils. Controlled challenge studies showed lower cecal counts of Salmonella Enteritidis, Salmonella Heidelberg, and Salmonella Typhimurium compared with non-supplemented controls. This consistency across strains highlights the robustness of the approach.

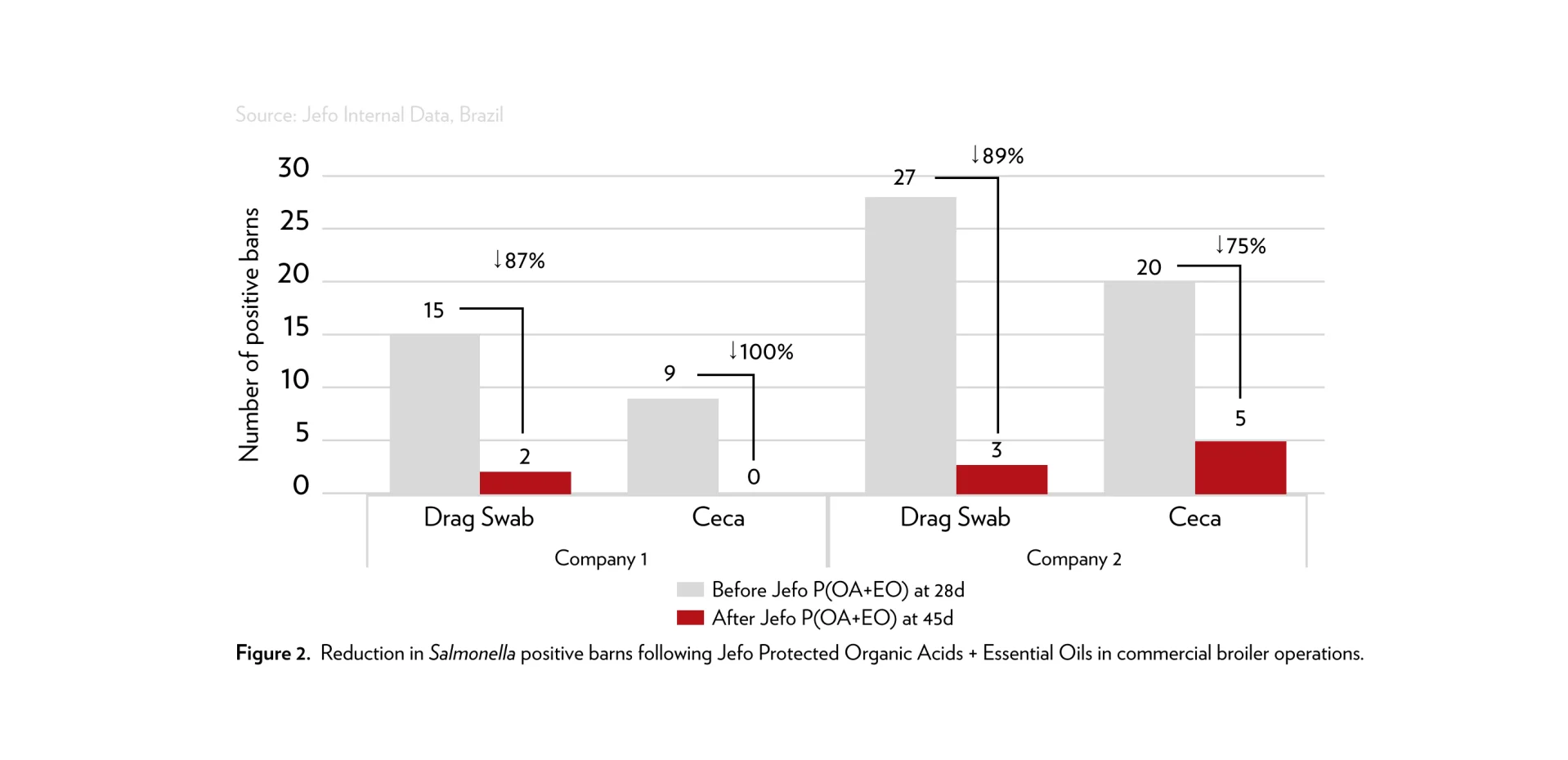

Reduction in Salmonella positive barns near market age

Field data from two commercial broiler integrators show a reduction in the number of Salmonella-positive barns following late-cycle supplementation with Jefo Protected Organic Acids + Essential Oils. Environmental drag swabs and cecal samples collected before supplementation (28 d) and after 7 days of supplementation (45 d) showed fewer positive barns in both companies. These results indicate that short-term supplementation near slaughter is associated with reduced environmental and intestinal Salmonella detection under commercial conditions.

Putting the evidence into context

Taken together, these findings show that Jefo Protected Organic Acids + Essential Oils offer a practical option for managing Salmonella pressure in broiler production. By reducing intestinal colonization before birds reach the processing plant, this nutritional strategy supports broader efforts to limit contamination risk later in the chain. Used alongside existing biosecurity and management practices, it provides producers with an additional tool to address a persistent industry challenge.

Tackling Campylobacter

Explore science-driven approaches to help control Campylobacter in your operation. See how innovative nutritional solutions can support performance and pathogen management.